- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-01 Origin: Site

Heavy-duty metal shelving offers unmatched durability and strength. But why should businesses choose it over regular shelving?

In this article, we’ll explore what makes heavy-duty metal shelving essential for industrial storage. You'll learn about its key features and why it’s perfect for warehouses and businesses that need reliable storage solutions.

Heavy-duty metal shelving is built for strength and durability. It is designed to handle the harsh conditions of industrial environments. These shelves are made to withstand heavy loads, ensuring that large or bulky items are stored safely and securely.

● Durability and Strength: Heavy-duty metal shelves are constructed from high-quality steel. This gives them the strength needed to hold heavy materials like industrial equipment and large machinery.

● Resistance to Wear and Tear: Unlike wood or plastic, metal shelves resist scratches, dents, and damage from heavy objects.

● Capability to Withstand Heavy Loads: Metal shelves can hold thousands of pounds of weight per shelf, making them ideal for warehouses and factories.

Heavy-duty metal shelves are often coated to resist corrosion. Surface treatments like galvanizing protect the shelves from rust and extend their lifespan, even in challenging environments.

● Corrosion Resistance: Galvanized coatings prevent rust, making these shelves perfect for environments with moisture or high humidity.

● Dust and Moisture Protection: These coatings also protect the shelves from dust, ensuring longevity in industrial settings.

In industrial spaces, organization is key. Heavy-duty metal shelving maximizes storage space, making it easier to store and access goods.

● Maximizing Storage Space: Adjustable shelves and vertical storage allow businesses to utilize every inch of space.

● Better Organization and Quick Access: These shelves keep items organized, so workers can find what they need quickly, improving workflow.

● Reducing Accidents: Sturdy metal shelves minimize the risk of collapse, making workplaces safer.

Compared to wood and plastic shelving, heavy-duty metal shelves offer several advantages, especially in demanding environments.

● Strength and Longevity: Metal shelves can support much more weight than wood or plastic and are less likely to wear down over time.

● Weather Resistance: Metal shelves perform better in extreme temperatures and humid conditions, unlike wood, which can warp, or plastic, which can crack.

Heavy-duty metal shelves are designed for maximum durability and strength. The key features that set them apart include:

● Materials Used: These shelves are often made from high-strength steel, such as Q235B steel, which provides superior strength and durability.

● Adjustable Shelf Heights: The ability to adjust the shelf heights allows for flexible storage options, accommodating items of varying sizes.

● Surface Treatments: Galvanizing or powder coating provides corrosion resistance, making the shelves suitable for tough industrial environments.

Heavy-duty metal shelving is built to handle demanding storage conditions. The design focuses on both strength and stability.

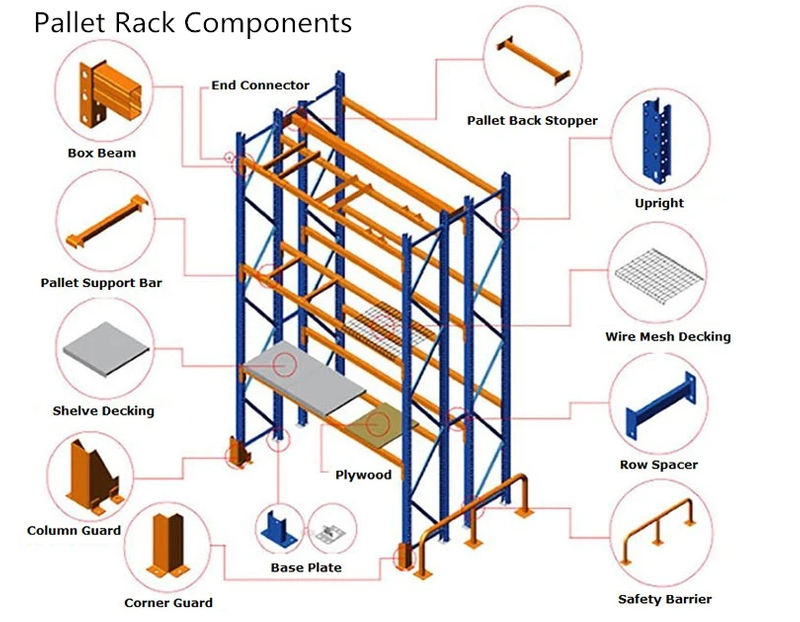

● Reinforced Steel Beams: These shelves feature reinforced beams that ensure strength and stability, even when storing heavy items.

● Strong Vertical Support Pillars: Vertical supports keep the shelving stable, preventing it from tipping or swaying.

● Robust Horizontal Beams: The horizontal beams provide support and evenly distribute the weight across the shelves.

● Heavy Load Capacity: These shelves are engineered to hold large loads, making them suitable for warehouses or factories.

There are several types of heavy-duty metal shelves, each designed for different storage needs.

● Heavy-Duty Warehouse Pallet Shelves: Ideal for storing bulk materials on pallets with easy forklift access.

● Customizable Long-Span Shelving: Perfect for storing large items or bulk goods, long-span shelving can be customized to fit your space and needs.

● Wire Mesh Storage Cages: These cages are used for secure storage, especially for smaller or valuable items. The mesh design allows for visibility and ventilation.

One of the greatest advantages of heavy-duty metal shelving is its flexibility. These shelves can be customized to meet specific storage needs.

● Modular Shelving Options: The modular design allows users to expand or adjust the shelves as needed, ensuring the storage system can grow with their business.

● Customization for Specific Needs: Whether it's adjusting shelf heights or choosing specific components, these shelves can be tailored to fit the items being stored.

Heavy-duty metal shelves are versatile and can be used in many industries where space, strength, and durability are crucial.

● Industrial Warehouses and Factories: These shelves are perfect for storing large items, tools, and raw materials in a warehouse or factory setting.

● Logistic Centers and Distribution Hubs: High-strength shelving helps organize goods efficiently, making the movement and storage of inventory easier.

● E-commerce Fulfillment Centers: In e-commerce, these shelves improve organization and help streamline packing and shipping processes.

Heavy-duty metal shelving is highly adaptable and can meet the needs of different industries:

● Manufacturing and Automotive Industries: These shelves can hold large mechanical parts, equipment, and tools, improving organization and access.

● Pharmaceuticals and Chemicals: Shelving ensures safe storage of sensitive or hazardous items, keeping them organized and easy to access while maintaining safety standards.

● Retail and E-commerce: Metal shelving helps efficiently store and sort products in warehouses and retail spaces, aiding inventory management.

Heavy-duty shelving isn’t just for large-scale operations. It also offers flexible solutions for businesses of any size.

● Flexible Solutions for Limited Space: Small businesses benefit from adjustable and customizable shelves that maximize their available space.

● Potential for Growth and Scalability: As your business grows, these shelves can be expanded or reconfigured to meet changing storage needs.

Heavy-duty metal shelving helps businesses maximize their available space and stay organized.

● Optimizing Vertical Storage: By utilizing vertical space, metal shelves help store more items in less floor area.

● Customization for Specific Storage Needs: Adjustable shelves allow you to tailor the shelving system to fit specific items, ensuring optimal organization and space utilization.

The ability to customize and adjust shelving makes it easy to optimize storage space.

● Adjustable Shelves: These shelves can be moved up or down to accommodate different item sizes. This flexibility helps improve space management and organization.

Investing in heavy-duty metal shelving can bring long-term cost savings.

● Long-Term Savings: With proper maintenance, these shelves last for many years. This reduces the need for frequent replacements.

● Low Maintenance and Durability: These shelves are made to endure heavy use and harsh environments, which means fewer repairs and lower overall maintenance costs.

Heavy-duty shelving can improve warehouse operations, making processes faster and more efficient.

● Faster Inventory Handling: Well-organized shelves allow for quicker access to items, speeding up inventory management.

● Reduced Downtime: When items are easy to find, downtime is minimized, allowing staff to focus on other tasks and improving overall productivity.

When comparing metal shelving to wood, metal comes out on top in many areas, especially in industrial environments.

● Strength and Load Capacity: Metal shelves can hold much heavier loads than wood shelves. This makes them ideal for storing large equipment or bulk items.

● Maintenance and Durability: Wood shelves are more prone to damage and wear, while metal shelves are resistant to scratches and dents. Metal’s durability ensures they last longer in high-demand environments.

● Performance in Challenging Environments: Unlike wood, which can warp, crack, or rot in humid or wet conditions, metal shelves are corrosion-resistant, making them perfect for harsh environments.

Plastic shelves are often used for light-duty storage, but they have some clear limitations compared to metal shelving.

● Load-Bearing Capacity: Plastic shelves can’t hold the same amount of weight as metal shelves. They are prone to bending or breaking under heavy loads.

● Environmental Factors: Plastic is more susceptible to temperature changes, and can warp or crack in high heat or extreme cold, making metal a more reliable choice for demanding environments.

Each shelving material—wood, plastic, and metal—offers its own set of advantages and disadvantages.

● Wood Shelves:

○ Pros: Aesthetic appeal, cost-effective for light-duty storage.

○ Cons: Susceptible to moisture damage, warping, and doesn’t support heavy loads well.

● Plastic Shelves:

○ Pros: Lightweight, resistant to rust and corrosion.

○ Cons: Limited weight capacity, can crack or warp under stress or extreme conditions.

● Metal Shelves:

○ Pros: Strong, durable, high load capacity, corrosion-resistant, ideal for harsh environments.

○ Cons: Higher initial cost, but the investment pays off with longevity.

Yes, heavy-duty metal shelves are highly customizable to meet various storage requirements.

● Adjustable Components and Tailored Designs: Many shelves come with adjustable parts, like shelves, beams, and connectors. This flexibility allows you to create a storage solution that fits your space and items perfectly.

● Custom Sizes, Shelving Heights, and Configurations: You can tailor the dimensions to match your available space. Whether you need shorter shelves or longer spans, these shelves can be designed to fit your needs.

Customized shelving offers many advantages, especially for businesses looking for efficiency and optimization.

● Space Optimization: Custom shelves ensure that every inch of your space is used effectively. This is particularly helpful in tight or awkwardly shaped areas.

● Efficient Handling of Unique Storage Items: Customized shelves allow for the efficient storage of items that require specific sizes or features, such as large machinery, equipment, or sensitive products.

Different industries have unique requirements, and custom shelving can be designed to meet these needs.

● Temperature Control: For industries that deal with sensitive materials, like pharmaceuticals, custom shelves can be designed to accommodate temperature control systems.

● Weight-Bearing Capacity: Shelves can be tailored to hold heavier items, such as industrial equipment or automotive parts, ensuring they remain safe and secure.

Choosing the right shelving starts with understanding your storage needs. Keep these factors in mind:

● Load Capacity, Shelf Depth, and Height: Ensure the shelves can hold the weight of your items. Consider the depth and height based on the size of the goods you plan to store.

● Material and Corrosion Resistance: For industrial settings, choose shelves made from high-strength steel or other durable materials. Look for corrosion resistance to ensure they last in tough environments.

● Dimensions of Your Space: Measure your available space before buying. Shelves should fit comfortably within the area, allowing for easy access and movement.

Different items require different shelving solutions.

● Heavy Machinery: These items need shelves with high load capacities and reinforced support beams.

● Light Parts or Small Items: Smaller items might require shelves with adjustable heights and smaller spacing between the shelves.

● Fragile Products: Shelves for fragile items should include features like smooth surfaces or additional security options to prevent damage.

Both pre-configured and custom shelving offer benefits, depending on your needs.

● Pre-Configured Shelving: These are standard options that may save time and money. However, they might not be perfect for unique storage needs.

● Custom Shelving: Tailored shelves can fit your exact space and storage requirements, but they often come at a higher cost and longer implementation time.

When selecting shelves, make sure you check the following:

● Weight Limits per Shelf: Ensure the shelves can safely support the weight of your stored items.

● Shelf Material Quality: Choose materials that are durable, corrosion-resistant, and designed for heavy-duty use.

● Safety Features: Check for any certifications or safety compliance to make sure your shelves meet industry standards.

Installing heavy-duty metal shelving can be a straightforward process, but the level of difficulty depends on the complexity of the shelves you choose.

● DIY Installation vs. Professional Services: Many heavy-duty metal shelves are designed for easy assembly, making them ideal for DIY installation. However, if you’re dealing with large, custom shelving, it’s better to hire professional services to ensure proper setup.

● Installation Guides and Tips: Most shelving systems come with detailed guides to help you through the installation. Following these steps carefully can save time and prevent mistakes.

To get the most out of your shelving, proper installation is essential.

● Ensuring Proper Foundation and Alignment: Make sure the floor is level and stable to support heavy loads. Improper alignment can lead to instability and unsafe conditions, especially when the shelves are fully loaded.

Maintenance is key to extending the life of your shelves.

● Regular Inspection for Stability and Safety: Check for any signs of damage, such as bent beams or loose fasteners. Tighten any loose bolts and ensure the shelves remain stable under load.

● Cleaning and Upkeep for Longevity: Keep shelves clean to avoid buildup of dirt, dust, or grease, which can affect their performance. A regular cleaning schedule will also help prevent rust or corrosion.

● How to Repair or Replace Damaged Parts: If a shelf is damaged, replace the affected part immediately. Many shelves have replaceable components like beams or panels, which can be swapped out without replacing the entire unit.

Heavy-duty metal shelving may require extra care when exposed to extreme conditions.

● Extra Tips for Maintaining Shelving in Wet, Humid, or High-Temperature Environments: For environments prone to moisture or temperature extremes, ensure shelves are made of corrosion-resistant materials. Regularly inspect for signs of rust or wear.

● Maintenance for Corrosion Prevention: Use anti-corrosion treatments, such as regular application of rust-resistant sprays or coatings, especially if shelves are exposed to high humidity or chemicals.

Heavy-duty metal shelving is evolving to meet the demands of modern industries. Key trends include:

● Integration with Automation and Smart Technology: Shelving systems are increasingly being integrated with automation tools and smart technology. This allows for automated inventory management and real-time tracking of stored items.

● Environmental and Sustainability Efforts in Manufacturing: Manufacturers are focusing on making shelving more eco-friendly by reducing waste and using sustainable materials.

Today’s warehouses are becoming smarter with the integration of technology.

● How Modern Metal Shelving Integrates with Automated Systems: Metal shelving can now be paired with automated systems like conveyor belts and robotic arms. This integration streamlines warehouse operations, speeds up inventory processing, and reduces human error.

As industries adapt to new needs, the market for heavy-duty metal shelving is growing and changing.

● Growing Demand in E-Commerce and Automated Warehousing: E-commerce growth and the rise of automated warehouses are driving demand for more efficient shelving solutions.

● Innovations in Design and Material Technology: Advances in design and materials are making shelves stronger, more versatile, and more cost-effective, allowing businesses to store and organize a wider range of products.

Sustainability is becoming more important in shelving production.

● Increasing Use of Recyclable Materials and Energy-Efficient Production Methods: Manufacturers are shifting to recyclable metals and energy-efficient processes to reduce their environmental footprint and meet stricter regulations on waste and emissions.

Investing in heavy-duty metal shelving improves efficiency, safety, and space utilization. For comprehensive solutions, explore our product range.

While the initial cost may be higher, the long-term benefits—like improved safety, organization, and productivity—make it a wise choice.

For the best shelving solutions, consider trusted manufacturers or suppliers known for quality and reliable products.

A: Heavy-duty metal shelves can hold from several hundred pounds to thousands of pounds per shelf, depending on the design and material.

A: The best materials for heavy-duty shelving include high-strength steel, such as Q235B, and galvanized steel for corrosion resistance.

A: Yes, with the right surface treatment, such as galvanizing, metal shelves can be used outdoors in harsh weather conditions.

A: Regularly inspect for damage, clean with a mild detergent, and check for rust or corrosion, especially in high-humidity areas.

A: Heavy-duty metal shelves can last for many years, often decades, if maintained properly and used in suitable environments.